After about a week of use the staff joints broke! I'm not terribly surprised. The 3D printed layers at the meeting point of pegs and staff sections were very thin and waving the staff put a lot of tension on those areas. The print layers at those parts simply separated after a time. For the next print I want to find and use some open source connectors from a site like Thingiverse. Another idea would be to run a threaded metal rod through the entire design, but this would be heavy and possibly interfere with future plans for buttons/wiring.

Wednesday, October 4, 2017

Prototype Broke!

After about a week of use the staff joints broke! I'm not terribly surprised. The 3D printed layers at the meeting point of pegs and staff sections were very thin and waving the staff put a lot of tension on those areas. The print layers at those parts simply separated after a time. For the next print I want to find and use some open source connectors from a site like Thingiverse. Another idea would be to run a threaded metal rod through the entire design, but this would be heavy and possibly interfere with future plans for buttons/wiring.

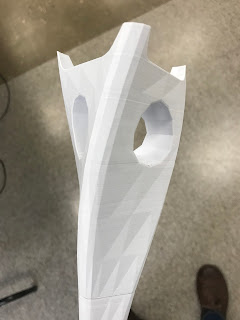

First Draft of Physical Staff

I wanted the staff's design, like the project, to be inspired by fluid motion. The first designs were based on curves and twisted geometry. My 3D modeling experience is in designing assets for games. So, designing a tool while focusing on form as well as real world function is proving to be even more challenging than I had already expected. Challenges we have discovered are:

- limited 3D print bed area requiring modular design

- the durability of these connections

- attachment point for the vive tracker

- finding the middle ground between ease/comfort of use and "cool" form

Admittedly the prototype solutions to these issues were pretty crude. Pegs and socket joints, epoxy/hot glue, and a design that proved too front heavy for comfortable long term use. But I look forward to applying these lessons to the next prop iteration.

The 3D print consisted of 4 staff sections printed on 3 Ultimaker 2 machines. The largest piece, the staff head, took about 12 hours to print. But overall the print came out virtually flawless.

Subscribe to:

Posts (Atom)